SPLICING TAPES FOR RELEASE PAPERS - 88-06 Specificaton & Trade Terms

| Model | 88-06 |

|---|

| Place Of Origin | united kingdom |

|---|

| Price Term | EX-Work |

|---|

| Payment Term | T/T |

|---|

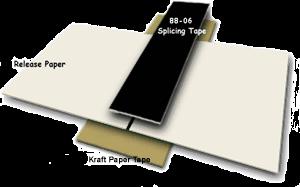

A unique range of single sided self-adhesive tapes for splicing surface treated release/casting papers as used in the manufacture of SYNTHETIC LEATHER. The system consists of:

For PU and PVC Casting Papers use:

TOP SPLICE

The tapes available for the top splice have a special release coat on the tape surface which ensures easy removal of the synthetic leather from the splice.

BACK SPLICE

A choice of 3 paper based tapes with very specific properties and easy to apply. Recommended for both PU and PVC release papers.

TOP SPLICE TAPES

For PU and PVC Casting Papers use

88-06 HT Polyester Silicone Splicing Tape - Black. Regarded as the best top slice available.

(see our data sheet)

For PVC Casting Papers only use:

88-01 HT Polyester Acrylic Splicing Tape - Clear . (see our data sheet)

BACK SPLICE TAPES

80-50 Adhesive Paper Tape - Green

0.10mm thick. This tape is flexible and conformable with a high level of adhesion, shear and temperature resisitance (200 deg C) .Ideal for PU production. (see our data sheet)

80-60 High Performance Kraft Paper Tape - Brown

0.16mm thick. This tape offers the highest level of adhesion, shear properties and temperature resistance :220 deg C short term. Especially recommended for PVC castings, heavily embossed papers and the newer type of smooth casting papers with surface coatings on the back. (see our data sheet)

80-55 Kraft Paper Splicing Tape - Brown

0.17 mm thick. It is competitively priced and offers excellent 'quick-stick' properties and temperature performance.

(see our data sheet)

General Properties and Application

1). The tape surface of 88-06 and 88-01 has been specially treated to ensure seperation of the synthetic leather from the splice in the same way as it separates from the release paper. This ensures continuous production of synthetic leather, with no downtime there is a production cost saving.

2). All tapes are easy to apply. Application with our free Plastic Applicator is recommended for a secure bond, including heavily embossed papers. Under cold conditions a warm iron can be moved over the splice to enhance adhesion. For the Back Splice abrasion of the release paper prior to applying the Back Splice will improve adhesion further.

3). The Splicing Tapes will withstand the temperature conditions encountered in the production of synthetic leather and will last through six or seven production cycles. What this means is that the tape can go through the production process 6-7 times, so when the casting paper is reused, the tape can also be reused too.

4). The Splicing Tapes can be stored up to 12 months prior to use, but they must be stored in dry conditions at around 22 deg C inside the original packaging. Protection from water/humidity, extreme temperatures and direct sunlight is necessary.

5). Note that PVC is cured at higher temperatures than PU. High tension occurs in the casting paper if production passes at high speed with high temperature, alternatively not if this passes through at lower speeds at lower temperatures. The tension could also be the way the line has been setup which the operator would know.

6). Our Customer Care Service is outstanding. Dispatch can be arranged worldwide by airfreight immediately after receipt of order.