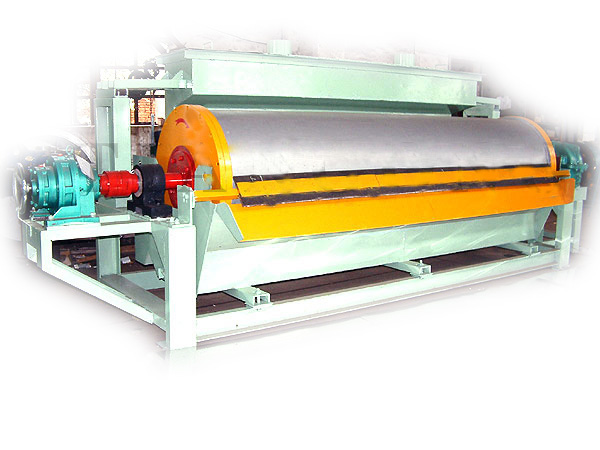

NCT Thickening Magnetic Separator - NCT1024 Specificaton & Trade Terms

| Model | NCT1024 |

|---|

| Place Of Origin | China (Mainland) |

|---|

| Price Term | EX-Work |

|---|

| Payment Term | T/T |

|---|

[MAS Baiyun NCT Thickening Magnetic Separator]

Brief

MAS Baiyun NCT -magnetic separators are newly developed strong wet magnetic separator for adjustment of magnetic mineral density in upstream and downstream operation stages of magnetic separation plants.

Feature

This magnetic separator is characterized by high recovery of strong magnetic minerals, large capacity and obvious thickening effect. Recovery of magnetic iron may reach above 99.5% and density may reach 50%~65% as feeding density is 20%~25%. Conventional dewatering tank and thickening pond occupying large area can be replaced by NCT thickening magnetic separator in thickening operation of strong magnetic minerals.

Through optimization design, magnetic system angle of the magnetic separator is large and the magnetic force distribution is more rational, resulting in a large beneficiation space on small drum, so that a lot of magnetic concentrate may pass through and valuable minerals may be recovered as more as possible. The magnetic separator unloads ore by a scraper in a non-magnetic zone. It is equipped with a washing pipe for concentrate and water amount may be adjusted so as to assure suitable density of the concentrate.

The magnetic separator may stabilized ore pulp density and obtain high recovery as the density of feeding ore pulp changes greatly.

Specifications of Installation and Adjustment

on Wet Drum Magnetic Separator

Equipment Installation Note

1.The equipment can be installed on the cement ground or operating table without ground screw for fixation, but must be level.

Convenience for adjustment of rinse for feed and concentrates, lubrication and magnetic declination

2.After finishing installation, equipment must operating without feeding for 3-4hours to inspect abnormal conditions, including gear-box, engine and bearing whose temperature is less than 30°C, and then can operate with feeding.

Equipment using and adjustment

1.According to water content of feed, to maintain the slurry concentration 25-35%.

2.Water for spraying concentrates need to be no contamination to avoid blocking the spraying holes and water pressure is about 2kg/cm3

3.At the bottom of the tank , there are two holes. That is incident pipe which is not used during regular production, while for maintenance downtime to clear the deposits in the bottom of the tank. When need to adjust the higher feeding density( 25-35% is better),the water amount for feeding spraying pipe should be not too large under control.

4.Forbid contaminations ,bulk ores, especially bulk iron in the tank to make the drum stuck, or damage the wearable rubber layer on the surface of the drum.

5.Often check gear-box and engine to find abnormal conditions, and resolve them.

Lubrication system

1.Rolling bearings need lubricating with petro grease once two weeks at least and change once 6-12 months completely.

2.Often check the oil note of the gear-box, If oil is below oil level line, should be added and change it once a year or so

Note of Turn On/Off

1.Start

Before driving motor start, do not feed in the material to the machine, Please note as follows:

(1)check the full machine ,be sure can easy to start to rotation.

(2)Check the surface of Drum and around have no any minerals.

(3)Check all parts lubricating oil, including gear-box and bearings

(4)Be sure the power is by your require.

2.Operation

(1)Open concentrate spray pipe and start engine to make drum rotating and watch the drum rotation’ way be sure the rotation way same as made in the machine. If not same, change the powder line.

(2)When the rotate is OK ,give the material to the feed fox.

(3)Begin to the magnetic separator.(produce)

3.Stop

(1)Stop feeding

(2)Open the incident water pipe to wash the deposits in the tank

(3)When the drum of magnetic separator have NO anything material, switch off the driving motor and turn off all the water pipes.

(4)Switch off the power

(5)Clean the around the machine.