Jlonghua Co.

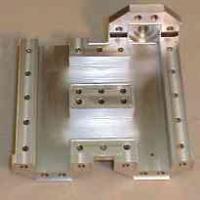

| About us | Our manufacturing capabilities include: Investment Casting 1 oz - 100 lbs casting sizes; 0.025' - 4' wall thickness; 0.005' per inch tolerance; Carbon & Stainless steel, copper based alloys; ASTM specification; Heat treatment and non-destructive testing. Die Casting Aluminum and Zinc; Castings from 0.05 lbs to 35 lbs; 100 ton to 1,600 ton capacity; low cost tooling; CNC Machining capability. Forging Close Die and Open Die; Carbon steel, stainless steel and alloy; Forging sizes: 20 lbs to 3,000 lbs; Heat Treatment; Machining; Pickling; In-house testing. Stamping Presses from 10 - 600 ton; Simple to progressive dies; 0.001' - 0.375' wall thickness; Ferrous and Non-ferrous materials; In-house tooling; Secondary operation. Plastic Injection Molding 5 - 500 pound parts; 1/4' to 5' wall thickness; 20 - 1000 Ton presses; Wide range of plastic materials; In-house mold design and build; CAD/CAM capability; Sonic welding; pad and screen printing. Shaped Moulds and Peformed Moulds and Gang-punch Moulds (Shutter;Ball carling;Cone convex and curling;Shape of scale(crack-shearing shaping);Press Bad or Press stem;Mark and stamping center punch;Shape of Bridge; Semi-cutting;Mark convex pattern;Frame Guide way of circart;Reserve Hole for Rapping; Gang Punched Hole. |

|---|---|

| Industry Focus | Cast & Forged |

| Business Type | Trading Company |

| Products/Services | Investment casting parts, die-casting parts, and plastic molds, stamping tools, CNC manufacture. |

| Our Markets | North America |

| No. of Employees | 11 - 50 People |

| Annual Sales Range(USD) | Below US$1 Million |