Akhil Brothers

| About us | Finishes: Polished Brass, Antiqued, Gold plated, Chrome, satin Chrome, Anodizing, Powder coated with protective layer of ordinary/electro-phoretic lacquer. Metals Used: Brass, Aluminium, Iron and Gun metal. New Product Development: We can develop any new product on the basis of sample/drawings/specifications. DETAILS OF IN-HOUSE FACILITIES CASTING/FORMING/FORGING Sand Casting :50 casting units Forging :400 T & 200 T Pressure Die Casting Equipments TOOL ROOMA full fledged tool room to cater to all in-house standard and any special requirements in Patten Making, Dies, Packaging dies, tools. The tool room has machines like Shaper, Milling Machine etc. PROCESS EQUIPMENTS Auto Lathe-8 2No. Auto Lathe-6 3No. Auto Lathe-4 6No. Manual Operational Lathe 5No. Radial Drilling Machines 12No. Trapping Machine 3No. Power Press 6No. Hand Press 5No. Auto Milling Machine 1No. Milling Machine 1No. Centerless grinding machine, automatic 1No. Surface Grinder (Automatic) 1No. Surface Grinder 2No. Pipe Bending Equipment 2No. Apart from above, other operations are done by hand, as most intricate art is involved which have to be done manually. Production Equipments Polish Machine (With Dust Removal & Collector system) 70 Nos. Automatic Lancer Machine 4 Nos. Ultrasonic Cleaning Equipment 4 Nos. Spray Paintings Booths 4 Nos. Lacquer Plant (with filtered air and vapors removal system) Liquid/Powder coating Booth 1Nos. Electric Furnaces for Stoving 3 Nos. METAL SURFACE FINISHING/ELECTROPLATING PLANT Complete automatic plant with facilities for 1Electro Phoretic Lacquering2Nickel Chrome plating3Chrome plating4Gold plating5Stain Nickel/Stain Chrome6Stain Gold7Antique/Black Antique8Brushed Nickel/BrushedChrome 9Various gloss/Matt finishes in many colours 10Black Nickel & Other Customer Specific Finishes. PACKAGING 1Blister packaging Machine & Complete system including sealing and cutting machines. 2Skin packaging machine 3Vacuum forming machine 4Moulding Machine 5Side and center Sealing Machine 6Dies and Moulds for the packaging requirement 7Four side sealing/welding machine. FINAL PACKAGING/CARTOINING Strapping Machine-Automatic SALIENT FEATURES Factory Covered Area 50,000 Sq. Ft. On going & proposed Expansion 50,000 Sq. Ft. (Facilities to be added) Material handling on continuous conveying mode at single as well as multilevel. PVDF plant CNC machines Expansions of range as well as equipments for the expanded range. Personnel Engaged Sand Casting 80 Rest of Department 200 Indirect 100 Connected load 325 KW Captive Power Generation 600 KW Total Installed Capacity 100 MT/Month Raw Material Used Important Honeycomb, Zinc & Copper Alloys & Ingots, Brass Sheets, Brass Pipes, Brass Rods, Copper Pipes & Sheets, Zinc & Zinc Alloys, Aluminium Rods, Pipes & Sheets Stainless Steel, Mild Steel in different form & Grades. Type of Products Manufactured Complete Range of precision components, assembly, turned parts. Hardware & Artware in Non-Ferrous & Ferrous materials. (e. G. Complete Range of Hardware for Doors, Windows, Cabinets, Bathrooms and others Current Export Market Spain, Germany, Sweden, U. K. U. S. A, Canada, South Africa, Australia, U. A. E, Ireland etc. Export turnover 100% of production nearly 85M. |

|---|---|

| Industry Focus | Construction Hardware, Paintings & Calligraphies, Mineral & Metals Agents, Non-ferrous Metal |

| Business Type | Manufacturer |

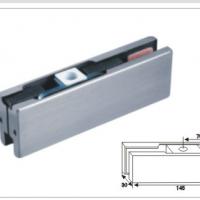

| Products/Services | Door and window hardware cabinet, fire place, stair, toilet seat hinges, curtain accessories, turned parts, precision components, art ware, home decorative handicrafts, gift items |

| Our Markets | Worldwide |

| No. of Employees | 101 - 500 People |

| Annual Sales Range(USD) | US$1 Million - US$2.5 Million |

| Year Established | 1994 |

| Certificates | yes |